We all know the phrase, “The Devil is in the Details”. When it comes construction projects these words couldn’t be more true. We all get excited to walk into a brand new or renovated facility. It is easy to be caught up in the fresh new look, updated lighting, new furniture and shiny tile flooring. In reality it’s the details that truly matter. It’s what you see when you start to take a closer look down in the corners. That speaks to the true quality of workmanship, and feeling that you’ve received good value for every project dollar spent.

Our clients are always so happy to walk into their finished project. Seeing it for the first time without all the ladders, workers, and equipment. Everything looks great! They are captivated by the overall look and feel of everything all shiny and new.

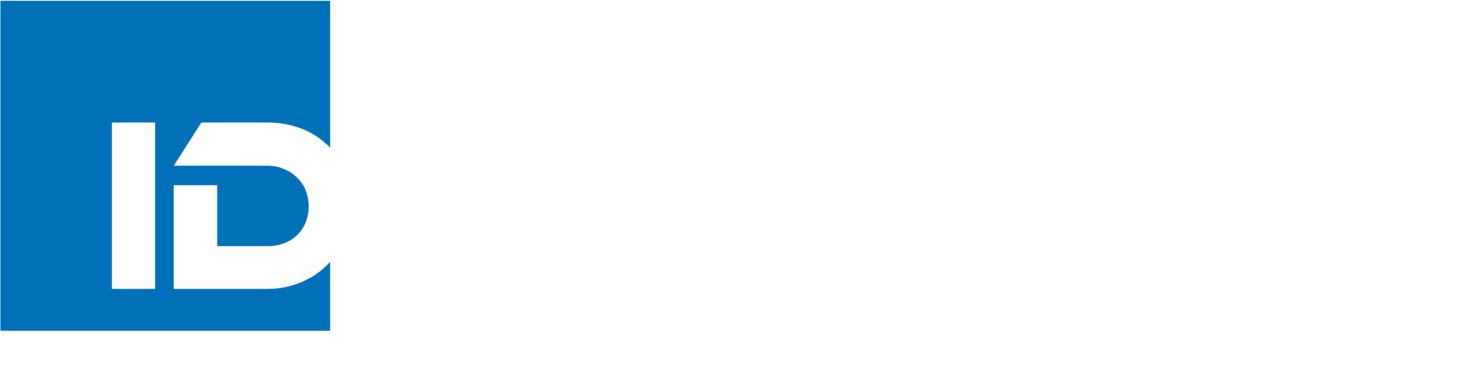

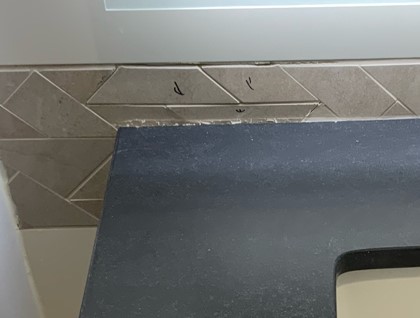

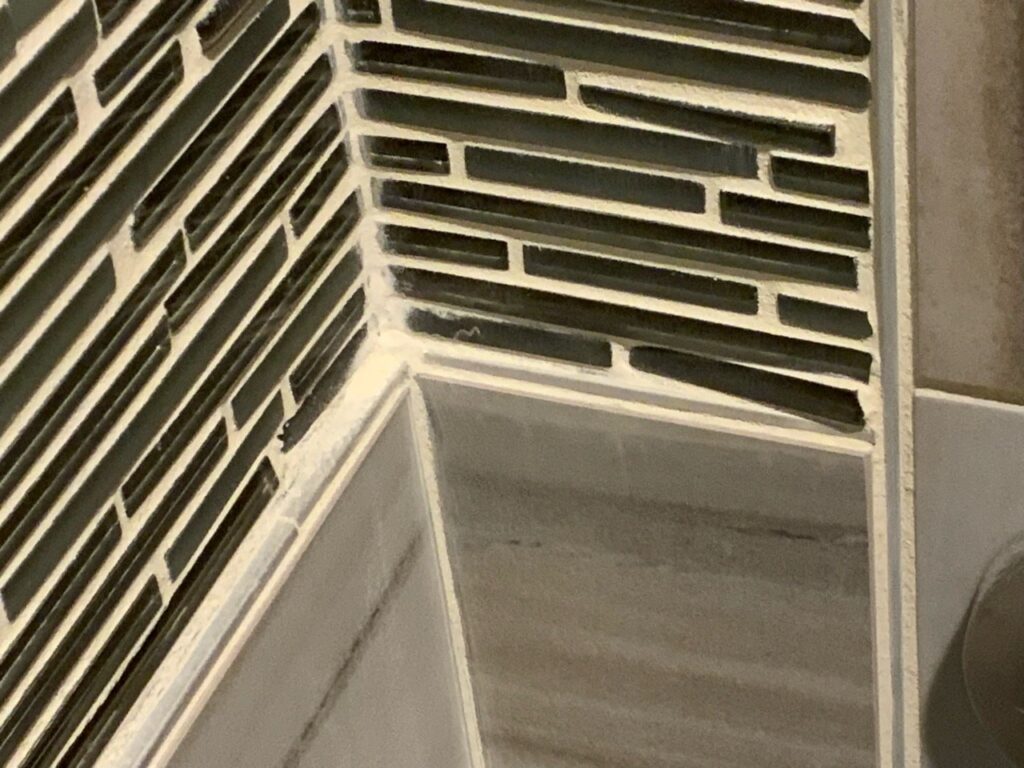

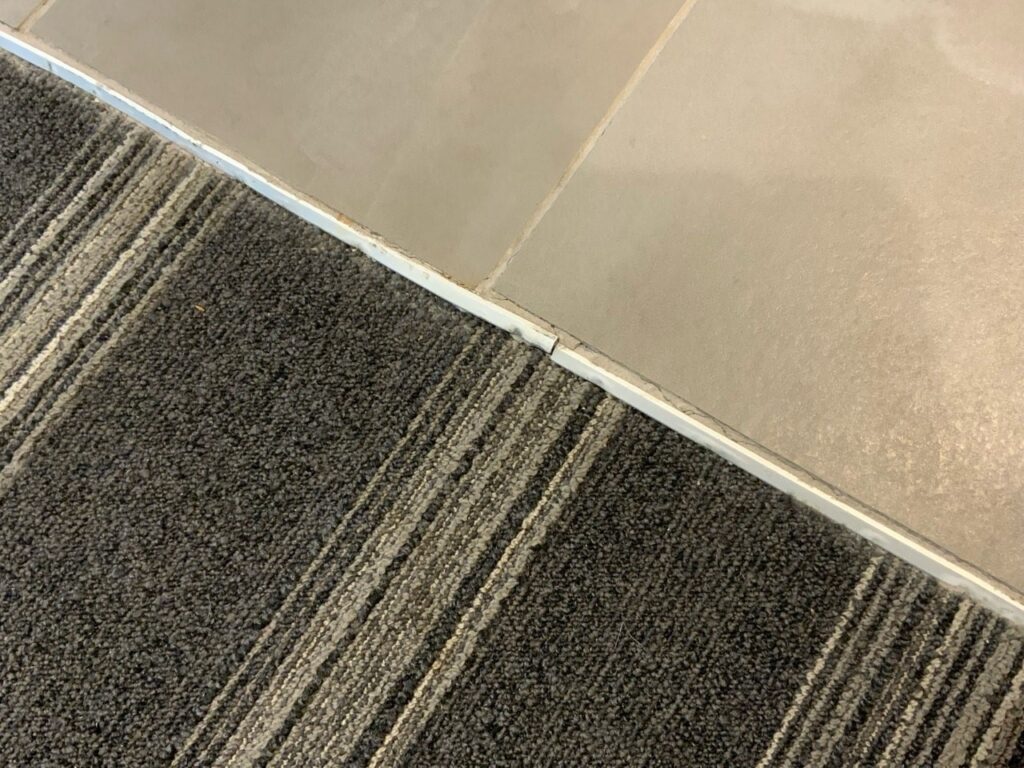

When you take your eye away from the overall picture and start looking closer at individual details. This is when the quality of work by the trades and the quality management of the General Contractor really come into focus. All the photos in this blog, are from projects that our clients thought looked great. The general contractors and subcontractors all felt that they had delivered a quality product. Closer inspection revealed a different story. This is not to say that the overall project wasn’t well delivered. It is always the details that can let down a really great project.

The images shared in this blog are just a small sample of what we have seen over the years. It should be noted that almost everything shared in these photos was eventually corrected or brought up to an acceptable standard. We have intentionally kept the identity of the projects anonymous as we don’t want to embarrass or shame anyone. Let’s take a bit of a deeper dive.

Here are four things to consider on your next dealership project.

1. The Devil is in the Details – Always

When we are out on a project walk throughs, we take a few moments to take in the big picture. Then, as we mentioned previously, we get down to the details. As we walk, we look down at the flooring, and the quality of its installation. We look up at the lighting and finish work of the ceiling. We’re looking behind, inside, and under everything we can. Bathrooms are a particular focus for us. There is usually significantly more tilework involved. We want to see that this work is done to a high level of quality. We’ve previously mentioned the importance of bathrooms in the dealership in a previous blog.

The general contractors usually aren’t overjoyed to see us doing this. As mentioned above, walking into any project, what you see at eye level likely isn’t raising any concerns. It comes down to the details. Where the walls meet the floor, in the corners, down at the baseboards, where two different materials meet, those are the areas that will tell you everything about the quality of the project.

We are constantly baffled on projects about things that would seem to be common sense. A painter who doesn’t put any protection down and gets paint on everything else. Baseboards go in and the installer leaves grout or glue smeared up on the newly painted walls. The flooring subcontractor installing a broken tile and using grout to fill in the damaged area. When things are out of square or two different materials don’t quite meet how they should, out comes the caulking gun. We’ve seen jobs where so much caulking was used it looked as if a child had used a wad of Playdough.

The Devil is in the Details, and its usually, but not always, at the end of the project. A deadline to doors open is only days or even hours away. This is where these shortcuts get taken. We like to say, “if it doesn’t look right, it probably isn’t”. It’s having an eye to catch and address all these small “oopses” before they are found by the client. Or their representatives. This is what really separates the detail-oriented project superintendent from the rest.

2. The Project Superintendent – Critical to Quality

In a previous blog we touched on the importance of a good project superintendent. We would like to reiterate that point. Every photo shown in this blog falls squarely on the general contactor’s project superintendent. Either they weren’t paying attention or failed to properly manage their subcontractors. We say “their subcontractors” because it is the general contractor who ultimately selects the subcontractors for any project.

Our clients pay for the project superintendent’s salary, cell phone, truck, and a host of other expenses. These are all rolled up under the monthly General Conditions fee. This is never a small number. It is a reasonable expectation that quality issues identified through the course of a project should never appear on the final punch list at the end of a job. Yet, its almost commonplace. We point to something we find, and the project superintendent will say “I wasn’t aware of it”. The other common default is “we’ll get it on the punch list”. Neither of these are the right response. They should be addressing these issues with the subcontractors at the time it’s identified. Addressing these issues at the end of the project is more difficult. We’ll come back to why when we talk about the punch list.

3. Protecting Finished Work – it’s not common sense

It is certainly frustrating to find quality issues and poorly executed details on projects. It is worse to visit a project and find finished work unprotected while other work goes on around or on top of it. At the top of our list is seeing a brand-new floor installed with no protection laid over it. Seeing subcontractors running hydraulic lifts over, or dropping skids of materials on, brand new unprotected floors makes us cringe. This almost always results in marks, scratches, or chipped and broken tiles.

We’ve seen a subcontractor cutting metal with a chop saw on top of freshly installed carpet in the customer lounge. All the while, the project superintendent stands there with us ignoring what is happening. When we point it out, their response is “we’ll clean it up”. They then default to “if we have any issues later, we’ll just address it on the punch list”. To add insult to injury, we found a cigarette butt that was put out on that same carpet. The project superintendent had no reaction and said they would steam clean our brand-new carpet.

You would think that protecting finished work would be an industry standard, but it’s not. We increasingly find general contractors skipping on protecting finished work. This is either to save cost or just out of laziness. Instead, they rely on fixing things with the punch list.

4. The Punch List

Too often we hear a general contractor say: “We’ll get it with the punch list”. It’s obvious that they’ve seen the issue, they know the work is subpar and unacceptable. Instead of addressing it, they hope it won’t be noticed. They wait until the end of the job. Then its on either the architect of record, or us as the owner’s representative, to find it and point it out.

The punch list should not be the place to tackle clearly unacceptable items that have previously been noted during construction. The time to address poor craftsmanship is the moment it’s identified. It is always a challenge getting the subcontractors to come back to a job when they have finished and moved on from it.

Fixing a few broken tiles or an issue with drywall doesn’t seem like a big issue. In reality, if construction is nearing completion, or worse yet, completed, it becomes a much larger project. Adjacent carpet is down, walls are painted, ceiling tiles are in place, and baseboards are installed.

Wrapping it Up

When it comes to the work that is done on any construction project, the devil is in the details. General contractors and the subcontractors they bring to your project should be held to a high standard. We look at a finished project and ask ourselves, would we accept this quality of work in our own homes? Just because it’s a commercial project doesn’t mean that “good enough” is acceptable. Knowing where to look and what to look for is also key.

Yes, take in the whole project and be proud of it. Don’t stop there. Take some time to look in the corners, at the tilework and all the grout joints. How is the fit and finish of all the cabinetry and furniture? Are there marks or small damage on walls or doorframes? All of it matters. Whether you feel you got a great price or think you are paid too much, none of what we have shown or addressed in this blog is acceptable on any project. Regardless of the price that is paid.