One of the hundreds of decisions, whether building a brand-new store, or renovating an existing facility, is choosing the right floor surface. While many manufacturer’s image programs clearly dictate flooring surfaces for front of house, the service drive, workshop and detail bays can sometimes be less clearly spelled out. Selecting the right flooring surface for these areas is more important than you might think. That’s why we’re looking at the four main flooring options for your service drive, workshop and detail bays in this blog.

In a previous blog we’ve talked about the fact that the service drive is your customer’s first impression again and again. The aesthetic appeal of a well-presented service drive, which absolutely includes the floor, is part of the impression that the customer formulates as they arrive for service.

Even with high-speed doors to keep the weather out, clients arrive with rain soaked or snow covered cars that drip. They track in water, snow, road grime and may even be dripping fluids such as oil and coolant. All of these can create a slip hazard for your customers as well as your service writing staff and porters.

As cars move into the workshop they bring all of the same potential slip hazards to your technicians. Splashed and spilled fluids like coolant and oil are just part of the day-to-day of repairing cars. Detail bays see not just water, but any number of cleaners or dressing chemicals daily. Flooring that keeps your staff’s footing firm helps keep them safe and productive. It also reduces potential slip and fall risk.

Trying to take all of this into account when planning your project is a lot to consider. We’re certainly no experts on the flooring topic, so we reached out to Superior Concrete Polishing and AutoStone USA to assist us in putting together information that will help you make informed decisions.

The Science Behind Slippery

First – a bit of the science behind floors and figuring out how slippery they are. We’ll keep this short.

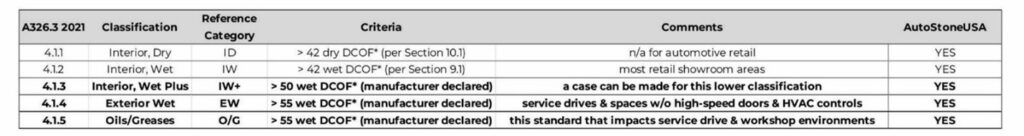

ANSI A326.3 & DCOF What are they? Why are they important?

ANSI A326.3 is a safety standard that tells us how slippery a floor is when it’s wet. It was created by the American National Standards Institute (ANSI), and it’s mostly used to test tiles and flooring. It uses a machine to measure how slippery a surface is. This is especially important in areas that can get wet – like your service drive, workshop or detail bays. The goal is to help prevent slips and falls.

DCOF (Dynamic Coefficient of Friction) is the number that comes out of the ANSI A326.3 test. It measures how much grip a person’s foot (or shoe) has on a floor while walking. Think of it like this: the higher the DCOF number, the less slippery the floor is. A DCOF of 0.42 or higher is generally considered safe for wet areas in commercial or public places.

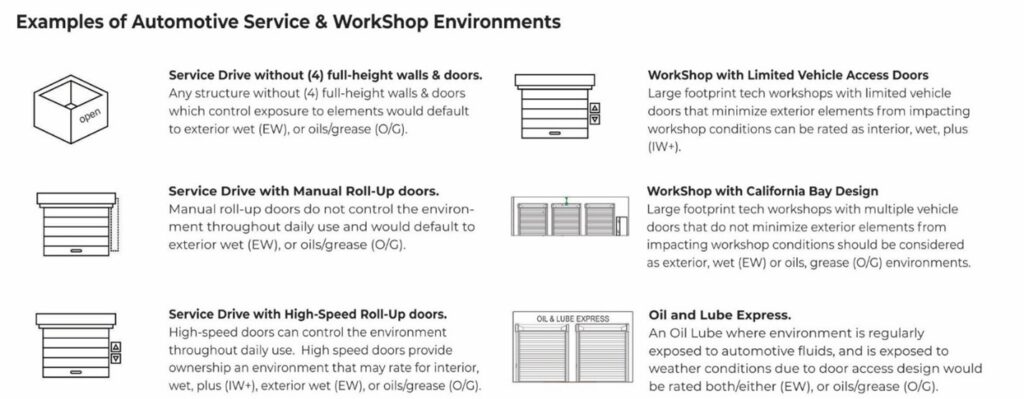

The below chart and examples, provided by Autostone USA, gives you a basic outline of the different ratings that would apply to your service drive and workshop

So, with all this background information absorbed, let’s look at the four main flooring options for your service drive, workshop and detail bays.

Here Are The Four Main Flooring Options for Your Service Drive, Workshop and Detail Bays

1. Polished Concrete

• Cost – More than sealed concrete & epoxy, less than tile (for initial material & installation)

• Installation – more labor-intensive than sealed concrete, epoxy, or tile

• Recommended Curing Time: 7-10 days to fully cure; no foot traffic for at least 24 hours & no vehicular traffic for 7 days.

• Maintenance – typically requires resurfacing every 3 years on average to maintain finish & protection against spills & stains. Resealing recommended semi-annually for high traffic areas.

• Aesthetic – Four levels of Shine, varying from matte to high-gloss achieved through a multi-stage process of grinding & polishing with progressively finer diamond abrasives. This process gradually reduces surface imperfections & increases reflectivity, leading to various gloss levels.

• Traction – Polished concrete is generally considered less slippery than sealed concrete because the polishing process creates a flat, porous surface that retains some of the natural traction of concrete. Polishing process does not remove the natural porosity of concrete entirely and a sealant that provides additional traction can be applied

2. Sealed Concrete aka Grind and Seal

• Cost – Generally least expensive of all options (polished, sealed, epoxy & tile)

• Installation – less labor-intensive than polished concrete, but more than epoxy or tile

• Recommended Curing Time: 7-10 days to fully cure; no foot traffic for at least 24 hours & no vehicular traffic for 7 days.

• Maintenance – typically requires reapplication every 3 years on average to maintain finish & protection against spills & stains.

• Aesthetic – Four levels of Shine (same as polished concrete) determined by the type of sealer used to achieve desired aesthetic.

• Traction – Although generally not slippery when wet with water-based liquids (which will absorb into the micro-pores of sealed concrete surfaces) can become slippery when oil & grease is applied. Oil & Grease will sit atop / coat the surface and can degrade finishes including anti-slip.

3. Epoxy Coating

• Cost – In-line with polished or sealed concrete, less than tile

• Installation – most labor-intensive of all (due to surface preparation & application process)

• Recommended Curing Time: 7 days for a full chemical cure recommended for vehicular traffic

• Maintenance – typically requires repairs / resurfacing every 1-3 years.

• Aesthetic – Offers a wide range of colors, gloss levels, and decorative techniques (such as faux marble or terrazzo looks); achieved by combining epoxy resins, colorants, and additives such as quartz grains or epoxy flakes.

• Traction – Epoxy is a smooth, non-porous coating that can be slippery when wet. However, epoxy floors offer many options for customization with slip-resistant additives or textured coatings to improve traction.

- Factors affecting slipperiness of epoxy:

- Epoxy Type: Different epoxy systems have varying levels of slipperiness. Oil-based epoxies are more prone to slipperiness.

- Application Method: A smooth, glossy epoxy finish is more likely to be slippery than a matte or satin finish.

- Slip-Resistant Additives: Epoxy flooring can be enhanced with many different levels of slip-resistant additives to improve traction.

- Sealing: Proper sealing can prevent moisture from penetrating concrete reducing slip resistance

4. Tile

• Cost – Most expensive option at initial material purchase & installation; however, upfront cost is often minimal & becomes MUCH less over time given its lifespan compared to the other flooring options discussed.

• Installation – least labor intensive of all, due to the surface preparation required for polished/sealed concrete or epoxy.

• Recommended Curing Time: 7-10 days to full curing process before heavy traffic or vehicular traffic

• Maintenance – With proper installation & care, porcelain tile floors can last up to 50 years for vehicular use; often 20-25 years before needing replacement

• Aesthetic – Offers widest variety of options for size, color, texture, and finish (i.e. matte to high gloss).

• Traction – Surface grit is baked into the tile in the kiln at production. Little to no degradation of traction surface over time. Impermeable to automotive fluids and grease.

• Repair – A damaged tile can be chipped out and replaced by a skilled installer, versus coatings that require complete replacement.

Keep it clean!

Whatever flooring surface you choose, make a commitment with your Service Director to keep it clean! With every shop project we do, we always budget for a high-quality walk behind floor scrubber with a second set of pads. One set for the shop floor and one set for the service drive. Having the cleaning crew run the machine through the service drive and the shop floor each night will not only keep the floors looking great for years to come, they’ll extend their service life too. A clean floor in the service drive speaks volumes to customers. A clean floor in the shop helps set the bar for the service team, and shows them you want them to have a clean space to do their work.

Wrapping it up

It was a long read, but there’s a lot of information to consider. When you look at the four main flooring options for your service drive, workshop and detail bays.

The reality is that the most expensive option is probably the best option. Our clients who have opted to go fully tile have never regretted their decision and their workshops really look “next level”. While the upfront cost is more significant, the ongoing maintenance is significantly less than all the other options.

That said, budgets have to be considered. Tiling a service drive and a complete workshop may just be too much of an expenditure. Maybe consider a hybrid solution. We’ve had clients who chose to install tile in the service drive, while selecting a different surface for the workshop floor and detail bays.

Grind & Seal, Epoxy, and Polishing are all less expensive routes that deliver a very nicely finished product. We’ve seen firsthand how the polishing process can really revive a tired, stained floor and lift the look of the entire space. That said, all three of these options will require more frequent ongoing maintenance than tile. Choose the best solution you can afford and look after your investment by keeping it cleaned well.