Whenever we embark on a service drive or workshop project, one of the topics we are sure to discuss are the shop doors. Sectional garage doors have been around for over 100 years, with roll up doors following somewhat soon after. We typically don’t give them too much thought. Until they don’t work. In reality, garage doors are integral to the look and feel of the facility. They are important to the security of the building. As well, they manage the flow of vehicles in and out of the facility. One of the more recent innovations in garage door technology is high speed doors. Roll up doors come at a cost premium to standard roll up doors. Even so, we have long held the belief that high speed doors are worth the investment.

Time is Money

It’s truly as simple as the age old saying “Time is Money”. In a dealership setting, there are multiple locations where roll up garage doors are required. Every Service Drive lane, Every workshop entrance and exit, and for externally loaded workshops, every single bay.

Consider the number of vehicles entering and exiting the workshop each day with a standard roll up door. Each technician has to wait 20-30 seconds each time they enter or exit the workshop. That’s approximately 1 minute per R.O. This is assuming the car only goes in and out once. Multiply this by the number of technicians on the team. Then add the number of cars per day. The numbers start to matter.

A quick online search with Microsoft’s AI Copilot says the average new car dealership repairs 600 cars per week. Or, 86 cars per day. Using standard garage doors, that equates to a loss of over an hour of production each day. That’s 7 hours a week, 28 hours a month, 336 hours a year! When you multiply that by the hourly labor rate, it really starts to add up!

Whether to consider Weather

I can hear my father now. “Close the door we’re not heating the neighborhood!” Whether its heated, cooled or both, almost every dealership in the country needs to condition their workshop space. Many will also have to do the same for their service drive. This is where high speed doors are worth the investment.

Rytec* high speed doors, have adjustable opening and closing speeds. They’re factory set to open at 60” (5 feet!) per second and close at 24” a second. Using a ten foot door as an example. It would take the door two seconds to open. It would remain open for four seconds for the car to pass (there are sensors to confirm the car has cleared the door). To close it would need five seconds. Total open time: 11 seconds versus almost a minute for a standard door. A high speed door can open allow a car to enter or exit, and close before a standard roll up door has completely opened.

It’s in the Numbers

Let’s do a little more math, with help from Microsoft’s AI Copilot… Assuming a 95 degree summer day, with a workshop interior temperature of 75 degrees. A 10’ x 12’ door, opening for 60 seconds would release approximately 144,000 btus of cooling. Reducing the opening time to the 11 seconds required for a high speed door drops the cooling lost to 28,800 btus. Remember, this calculation is for one car going in or out one door, one time! The hot cars entering the workshop are already going to make the cooling system work harder. Why drive up cooling costs even further by letting all the cool air escape while standard garage doors open and close?

The same sorts of calculations can be applied to heating work shops and service drives in the cold northern climates. It all boils down to this. The longer a door is open the more heating and cooling systems have to work. The more money it costs to keep the workshop at the desired temperature for the technicians. Between lost productivity and increased climate control costs, the math really starts to show that high speed doors are worth the investment.

A little more about Rytec

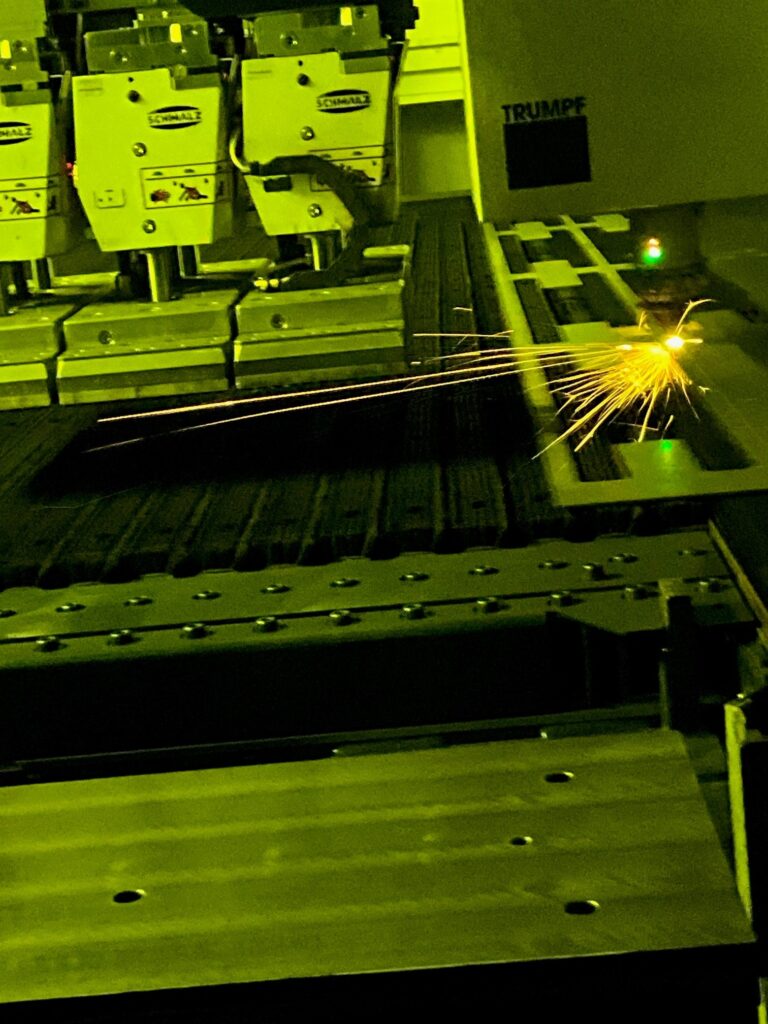

For a number of years we’ve been recommending Rytec high speed doors to our clients for their projects. Rytec doors are manufactured in the US. Their team is 100% focused on providing a high quality product with excellent after sale support. There’s a great quote in their lobby that really underscores their commitment. “What have you done for the customer today?”

Rytec has recently invested approximately 20 million dollars in new machinery and systems in their production facilities. This allows them produce almost all of their subcomponents in house. It’s all part of their commitment to deliver ready to install high speed door systems to customers with as short a lead time as possible. This end to end manufacturing also helps minimize down time if a customer’s door needs replacement parts.

Wrapping it Up

All the above math is our own assumptions and calculations. As they say in so many commercials “Your results may vary.” We hope it will give you pause to consider that stepping up for high speed doors could pay long term dividends in both service productivity and facility operating costs. There are certainly other high speed door offerings in the market, but Rytec is the only manufacturer to do so exclusively. Do your research, consider the costs, and the potential cost savings. We’re pretty sure you’ll come to the conclusion that high speed doors are worth the investment.

*Full transparency ID Automotive was recently invited by Rytec doors to come and tour their manufacturing facilities in Wisconsin and learn more about the technology behind high speed doors.